RESISTOR

INTRODUCTION

Have you seen any electric kit, if yes then, you must have seen that there are many electrical components on them? but do you know, which components are the most of them, in fact, most of them are resistors? see below there is an inside picture of the mobile charger kit. Here, you will see that most of them are resistors.

so, a question came to mind that what’s actually a resistor? well, today’s in this article, we will learn everything about resistors in detail.

But first of all, you people understand that resistors are the most common components which are used in electrical devices, without Resistors electrical engineering is somewhere incomplete.

Due to a large development in electrical engineering, engineers have developed different kinds of resistors as per need. Different types of resistors have different properties because of this, these resistors are to be going used in a different kind of electrical machines where it performs different functions. So we must know about these resistors, their types, and applications where they can be used. So let’s start –

WHAT IS A RESISTOR?

The resistors are self-explanatory terms. A resistor means a device that resists something and this something is what? this something is nothing but the electric current. A resistor is connected to any electrical circuit to minimize the flow of electric current. So we can define a resistor as follow:

Definition : It is a passive device which is used in electrical circuit to minimize the flow of electric current in others words a device which resist the flow of electric current.

You can see the picture of a resistor below :

SYMBOLS

Well, we have to know that what is a resistor? But how can we recognize it in any electrical circuit? For recognition, there are two main symbols of Resistors that are used in electrical physics.

The oldest symbol is still widely used in North America and consists of a jagged line representing the wire used in a resistor. The other symbol of the resistor is a small rectangle, and this is often termed the international resistor symbol and it is more widely used in Europe and Asia.

UNITS

The ability of a resistor to resist electric current in any electrical circuit is called resistance. Read more about resistance here.

The unit of resistance is ohm which is symbolically denoted as Omega (Ω). The value of resistance of any resistor can be seen quoted in ohms (Ω) such as – thousands of ohms or kilohms i.e kΩ, millions of ohms or megaohms i.e MΩ.

If the value of resistance in any circuits is written like 10k may be seen meaning 10 kilohms, or 10 kΩ. The Omega sign is often omitted and the decimal point is replaced by the multiplier: e.g. 1R5 would be 1.5 Ohms, 100R is 100Ω, 4k7 is 4.7 kΩ, 2M2 is 2.2MΩ, and so forth.

TYPES OF RESISTORS

There are various types of resistors are available in the markets based on their shape, size, material by which they made, efficiency, and applications. We will discuss all possible types of Resistors, one by one in detail.

Basically, there are two types of Resistors:

- Linear Resistors

- Non-linear Resistors

LINEAR RESISTORS

It is those resistors, which resistance values change with the applied voltage and temperature. In other words, we can say, a resistor, which current value is directly proportional to the applied voltage is known as linear resistor.

Generally, two types of resistors have linear properties. These two Resistors are :

- Fixed Resistors

- Variable Resistors

FIXED RESISTORS

It is a resistor which value can’t be changed. The resistance value for fixed resistors is fixed.

Types of Fixed resistors.

- Carbon Composition Resistors

- Wire Wound Resistors

- Thin Film Resistors

- Thick Film Resistors

CARBON COMPOSITION RESISTORS

We have seen that fixed resistors are four types and one of them is carbon composition resistors. These fixed resistors are called carbon composition resistors because it is made from the mixture of a granulated or powdered carbon or graphite, insulation filler, or a resin binder.

In these types of resistors, the ratio of the insulation material determines the actual resistance of the resistor. The insulating powder i.e binder made in the shape of rods and there are two metal caps on both ends of the rod.

At both ends, there are two-conductor wires of the resistor for easy connectivity in the circuit. Resistors are joined to the circuit via soldering.

At the uppermost surface, a plastic coat covers the rods with different color codes (printed on it), which denote the resistance value. They are available in 1 ohm to 25 mega ohms and in power rating from ¼ watt to up to 5 Watts.

CHARACTERISTICS OF FIXED RESISTORS

- It is very cheap and small in size so it occupies less space.

- They are reliable and available in different ohmic and power ratings.

- Easily connected to the circuit and withstand more voltage.

- Fixed Resistors are less stable it means their temperature coefficient is large.

- It makes more noise as compared to the other Resistors.

WIRE WOUND RESISTORS

Wire wound resistor is formed from the insulating core or rod by wrapping around a resistive wire. The resistance wire is usually Tungsten, manganin, Nichrome, or nickel or nickel-chromium alloy and therefore the insulating core is formed of porcelain, Bakelite, press bond, or ceramic clay material.

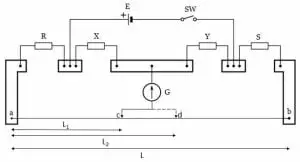

The manganin wire wound resistors are very expensive and used in sensitive test equipment e.g. Wheatstone bridge, etc. they’re available within the range of two watts up to 100-watt power rating or more. The ohmic value for these sorts of resistors is 1 ohm up to 200k ohms or more and maybe operated safely up to 350°C.

in addition, the facility rating of a high power wire wound resistor is 500 Watts and therefore the available resistance value of those resistors are is 0.1 ohm – 100k Ohms.

ADVANTAGES AND DISADVANTAGES OF WIRE WOUND RESISTORS

Wire wound resistors make lower noise than carbon composition resistors. Their performance is well in overload conditions. they’re reliable and versatile and may be used with DC and audio range. The disadvantage of wire wound resistors is that they’re costly and can’t be utilized in high-frequency equipment.

APPLICATION OF WIRE WOUND RESISTORS

- It is used where high sensitivity, accurate measurement, and balanced current control are required. e.g shunt with ampere meter.

- It is used in high-power ratings devices and equipment.

- Used in testing and measuring devices.

THIN-FILM RESISTORS

These resistors are made of high grid ceramic rods and resistive material. A very thin layer of conducting material is overlaid on the insulating rod. This rod is made from high-quality ceramic material or glass. Further, there are two types of thin-film resistors, they are :

- Carbon Film Resistors

- Metal Film Resistors

CARBON FILM RESISTORS

Carbon Film resistors contain a protecting material bar or center made of high evaluation clay material which is known as the substrate. An extremely slight resistive carbon layer or film overlaid around the rod.

ADVANTAGES OF CARBON FILM RESISTORS

- It is widely used in electronics because these resistors create very little noise.

- It has a wide operating range.

- It is very stable as compared to solid carbon resistors.

METALS FILM RESISTORS

The construction of metal film resistors is the same as carbon film resistors. But the difference between them is that in metal film resistors, metals are used as a resistive film instead of carbon film.

This metal resistive film is made of a mixture of metal oxides, nickel-chromium, or a mixture of metals and glass. This resistive film mixture is called the metal glaze.

ADVANTAGES OF METALS FILM RESISTORS

- It is very tiny, cheap and reliable.

- Its temperature coefficient is very low (±2 ppm/°C).

- Less noisy.

THICK FILM RESISTORS

Thick film resistors are the same as thin-film resistors, but the difference between them is that there is a thick film instead of a thin film layer of resistive material around. That’s why this resistive is called Thick film resistors.

Further, Thick Film Resistors are divided into three additional types.

- Metal Oxide Resistors

- Cermet Film Resistors

- Fusible Resistors

METALS OXIDE RESISTORS

By oxidizing, a thick film of Tin Chloride on a warmed glass rod (substrate) is the straightforward strategy to make a Metal oxide Resistor. These resistors are accessible in a wide scope of resistance with high-temperature strength. Furthermore, the degree of working noise is exceptionally low and can be utilized at high voltages.

CERMET OXIDE RESISTORS

In the cermet oxide resistors, the inside region contains artistic protection materials. And afterward a carbon or metal compound film or layer folded over the resistor and afterward fix it in a ceramic metal (which is known as Cermet). They are made in a square or rectangular shape and leads and pins are under the resistors for simple establishment in printed circuit sheets. They give a steady activity in high temperatures because their qualities don’t change with a temperature change.

FUSIBLE RESISTORS

Fusible Resistors are the same as wire-wound Resistors. When the power rating in the circuit exceeds the specific value then it gets fused means it breaks the circuit and makes it open. Having this property these are called fusible Resistors.

Fusible Resistors perform dual work in the circuit. It works like a fuse as well as a resistor that resists the flow of electric current.

They are utilized generally in TV Sets, Amplifiers, and other costly electronic circuits. For the most part, the ohmic value of fusible resistors remains under 10 Ohms.

VARIABLE RESISTORS

As the name shows, those resistors which value can be changed through a dial, handle, and screw or physically by an appropriate method. In these kinds of resistors, there is a sliding arm, which is associated with the shaft and the value of resistance can be changed by turning the arm. They are utilized in the radio collector for volume control and tone control obstruction.

There are three types of variable Resistors, these are:

- Potentiometers

- Rheostats

- Trimmers

POTENTIOMETERS

The potentiometer is a three-terminal device, which is utilized for controlling the degree of voltage in the circuit. The resistance between the two outer terminals is constant while the third terminal is associated with moving contact (Wiper) which is variable. The worth of resistance can be changed by pivoting the wiper which is associated with the control shaft.

Potentiometers can be utilized as a voltage divider and these resistors are called variable composition resistors. They are accessible up to 10 Mega Ohms.

RHEOSTAT

A rheostat is a variable resistor that is utilized to control the electric current in any circuit. They can change the resistance in a circuit without any interference.

The construction is basically the same as the construction of a potentiometer. It utilizes just two associations, in any event, when three terminals (as in a potentiometer) are available.

The first association is made to one end of the resistive component and the other association with the wiper (sliding contact). Rather than potentiometers, rheostats need to convey a huge current.

Subsequently, they are generally developed as wire wound resistors. The resistive wire is twisted around an insulating ceramic core and the wiper slides over the windings. A rheostat is also known as tapped Resistors and variable wire wound resistors.

TRIMMERS

There is an additional screw with Potentiometer or variable resistors for better efficiency and operation and they are known as Trimmers. The value of resistance can be changed by changing the position of the screw to rotate by a small screwdriver.

They are produced using carbon composition, carbon film, cermet, and wire materials and are accessible in the scope of 50 ohms up to 5 megaohms. The power rating of Trimmers potentiometers is from 1/3 to ¾ Watts.

NON-LINEAR RESISTORS

Non-linear resistors are those resistors, where the current moving through it doesn’t change as indicated by Ohm’s Law in any case, changes with change in temperature or applied voltage.

Likewise, if the streaming current through a resistor changes with a change in internal heat level, at that point these sorts of resistors are called Thermisters. If the streaming current through a resistor change with the applied voltages, it is known as a Varistors or VDR (Voltage Dependent Resistors).

The non-linear Resistors are the following types :

- Thermistor

- Varistor (VDR)

- Photo Resistor or Photo Conductive Cell or LDR

THERMISTOR

Thermisters is a two-terminal resistor that is sensitive to temperature. As such, Thermisters is a kind of factor resistor that sees the adjustment of temperature.

Thermisters are produced using cobalt, Nickel, Strontium, and the metal oxides of Manganese. The Resistance of a Thermister is inversely proportional to the temperature, for example, resistance increases when temperature decreases and vice versa.

It means, thermistors have a negative temperature coefficient (NTC) however there is likewise a PTC (Positive Temperature Coefficient) which a produced using PID barium titanate semiconductor materials and then their resistance increases when the temperature increases.

VARISTOR (VDR)

Varistors are voltage Dependent Resistors (VDR) that are utilized to wipe out the high voltage drifters. As such, a unique kind of variable resistor used to shield electric circuits from damaging voltage spikes is called a varistor.

At the point, when voltage increases (because of lighting or line issues) across an associated sensitive gadget or framework, at that point it decreases the degree of voltage to a protected level i.e it changes the degree of voltages.

PHOTORESISTORS OR PHOTOCONDUCTIVE CELL OR LDR (LIGHT DEPENDENT RESISTORS)

Photoresistors or LDR (Light Dependent Resistors) are the resistors whose terminal value of the resistor changes with the intensity of the light. Please note that the photo means light.

In other words, we can say that photoresistors are those resistors whose resistance values are getting changed by the falling of light on their surface. So having this property, these resistors are called photo Resistors or photoconductive cells or LDR (Light Dependent Resistors). And the material which is used to make these kinds of resistors is called photoconductors, e.g. cadmium sulfide, lead sulfide, etc.

When light falls on the photoconductive cells (LDR or Photoresistor) then due to the light energy, there increase the free charge carriers (electron-hole pair).

These increased free carriers reduce the resistance of semiconductor material, (i.e. the quantity of light energy is inversely proportional to the semiconductor material). It means photoresistors have a negative temperature coefficient.

APPLICATION AND USES OF PHOTORESISTORS OR LDR

These sorts of resistors are utilized in criminal alert, Door Openers, Flame finders, Smock indicators, light meters, light-activated relay control circuits, modern and business programmed street lamp control, and photographic gadgets and supplies.

APPLICATION OF RESISTORS

Normally both types of resistors (linear and non-linear) are used for the following purposes:

SOME USES OF RESISTORS

- For controlling and limiting the electric current

- To changing the electrical energy into heat energy

- Used as a shunt in Ampere meters

- Used as the multiplier in a Voltmeter

- For controlling temperature

- For controlling voltage or Drop

- For protecting the electrical circuit, e.g. Fusible Resistors

- In the school physics practicals.

- Heater, iron, immersion rod, etc.

- Widely used in the electronics industries.

![Wheatstone bridge | working principle, construction and its derivation [class 12].](/storage/2021/06/wheatstone-bridge-300x240.jpg)